Best environmental investment solution

Double Rotary Egg Tray Making Machine

7000~12000PCS/H

What's Double Rotary egg tray production line

The Double Rotary Egg Tray Production Line is a cutting-edge system designed for the mass production of egg trays. In this advanced setup, pulp is fed into a double rotary forming machine equipped with two rotating drum molds. These molds shape the pulp into egg trays using vacuum suction. The double rotary technology not only allows for continuous and rapid tray formation but also significantly enhances efficiency and production capacity. This production line is widely used in the packaging industry for producing egg trays, which are essential for the safe transport and protection of eggs.

High Efficiency

The double rotary technology significantly increases production speed, enabling the production of a large quantity of egg trays in a short period.

Energy Efficiency

Modern drying systems and optimized processes help reduce energy consumption.

Quality Control

The process ensures uniform thickness and smooth surfaces of the egg trays, which are essential for durability and aesthetic appeal.

Production Process

Drying system

Pulp Preparation System

The process of mixing bagasse, bamboo or wood pulp with water or chemical solutions and processing it into a pulp-like substance

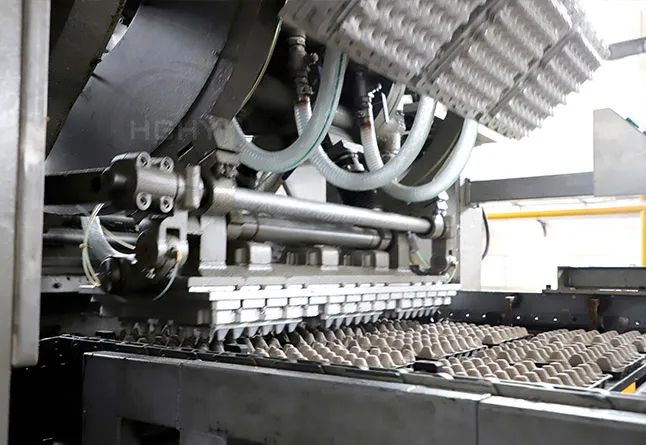

Forming System

The slurry is used to create products through vacuum suction within the forming mold. Afterward, the pulp molded items are transferred using a transfer mold and directed to the subsequent drying line.

Technical Parameters

- Sold out for more than 150 lines

- High efficient 6 layer dryer

- Automatic conveying and automatic hot pressing system

- 3rd generation of mature and classical after press

- High efficient 6 layer dryer

- Automatic conveying and automatic hot pressing system;

- 3rd generation of mature and classical after press.

- Excellent performance of rotary forming technology;

- Unique patented hot pressing mechanism;

- Labeling printing machine is optional.

| Model | 7000B2C | 9000B2C | 12000B2C |

| Molding Machine | High Speed Double Rotary Technology | ||

| Molding Faces | 6 Faces Forming + 6 Faces Transfer | ||

| Platen Size | 850 × 460 mm | 1250 × 460 mm | 1650 × 460 mm |

| Drops per Minute | 50-60 Drops | ||

| Drying Oven | 10 Layers | ||

| Drying Energy | Diesel / Natural Gas / LPG / LNG etc, or Boiler System of Steam / Conduction Oil | ||

| Standard Capacity / Hr | 7,000 pcs | 9,000 pcs | 12,000 pcs |

| Standard Capacity / Day | 168,000 pcs | 216,000 pcs | 288,000 pcs |

| Floor Plan (m) | 72 × 18 × 8 | 90 × 18 × 8 | 90 × 24 × 8 |

| Labor / Shift | 5~6 | 5~6 | 6~7 |

| Raw Material | Waste Paper | ||

| Max Product Height | 70 mm | ||