Best environmental investment solution

Molded Pulp Insert Machine

Base On Products

What's Molded Pulp Insert line

Molded Pulp Insert Machine is specialized equipment for producing a wide range of sustainable packaging products from recycled paper pulp. It can manufacture customized inserts such as protective trays, electronic product inlays, industrial packaging, cosmetic holders, food containers, and other pulp-based packaging solutions. By integrating pulping, molding, drying, and hot pressing processes, the machine delivers eco-friendly, biodegradable, and shock-resistant products that replace traditional plastic or foam packaging, ensuring both environmental responsibility and cost-effective mass production.

Eco-Friendly & Sustainable

Uses recycled paper pulp, 100% biodegradable and compostable.

Cost-Effective

Reduces raw material costs by using waste paper and simplifies packaging supply chains.

Versatile Production

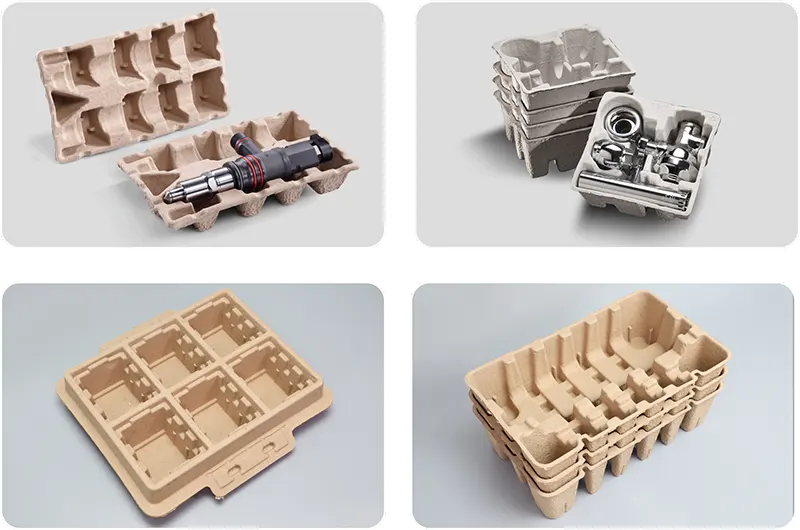

Capable of producing trays, inserts, cosmetic holders, industrial packaging, and food containers.

Production Process

Drying system

Applying sufficient hot air uniformly across the surface of the pulp molding items to eliminate the moisture evaporating from the damp products. Following the drying process, they are directed towards automatic stacking and shrink wrapping for packaging.

Pulp Preparation System

The process of mixing bagasse, bamboo or wood pulp with water or chemical solutions and processing it into a pulp-like substance

Forming System

The slurry is used to create products through vacuum suction within the forming mold. Afterward, the pulp molded items are transferred using a transfer mold and directed to the subsequent drying line.

Technical Parameters

- Cost-Effective Investment – Less expensive than rotary machines, making it ideal for small to medium-scale production with quick ROI.

- Simple Operation & Maintenance – Easy-to-use structure, reduced complexity, and lower maintenance requirements.

- Flexible Production – Supports multiple mold changes to produce various pulp trays, inserts, cosmetic holders, and industrial packaging.

- Energy Saving & Stability – Advanced drying system ensures low energy consumption, high stability, and consistent product quality.

- Scalability – Suitable for small-scale startups while also adaptable for larger production expansion.

- Eco-Friendly Materials – 100% biodegradable pulp-based products made from recycled paper, reducing plastic and foam usage.

- Durable & Protective Packaging – Strong shock absorption and reliable cushioning, ensuring product safety during transportation.

- Customizable Design – Tailored molds for different shapes, sizes, and industries including electronics, cosmetics, food, and consumer goods.

- Efficient Production Line – Integrated pulping, forming, drying, and hot pressing processes for streamlined mass production.

- Sustainable Business Growth – Helps manufacturers align with global trends toward green, eco-conscious packaging solutions.

| Model | Reciprocating Production Line | ||

|---|---|---|---|

| Machine Structure | Forming Upper Platen x1; Forming Lower Platen x1; If Platen size is bigger, Upper platen move out automatically, Or to match with dryer by auto feeding. | ||

| Platen Size | Different sizes of plates would be customized on demand | ||

| Forming Method | Reciprocating | ||

| Matching Dryer | Natural Drying or Drying Tunnel Or single Layer Dryer as Optional | ||

| Heating Type | Thermal Oil, Natural Gas or Steam Heating | ||

| Control By | PLC + Touchscreen | ||

| Designed Capacity | Depends on Products | ||

| Product Height Range | ≤150mm | ||