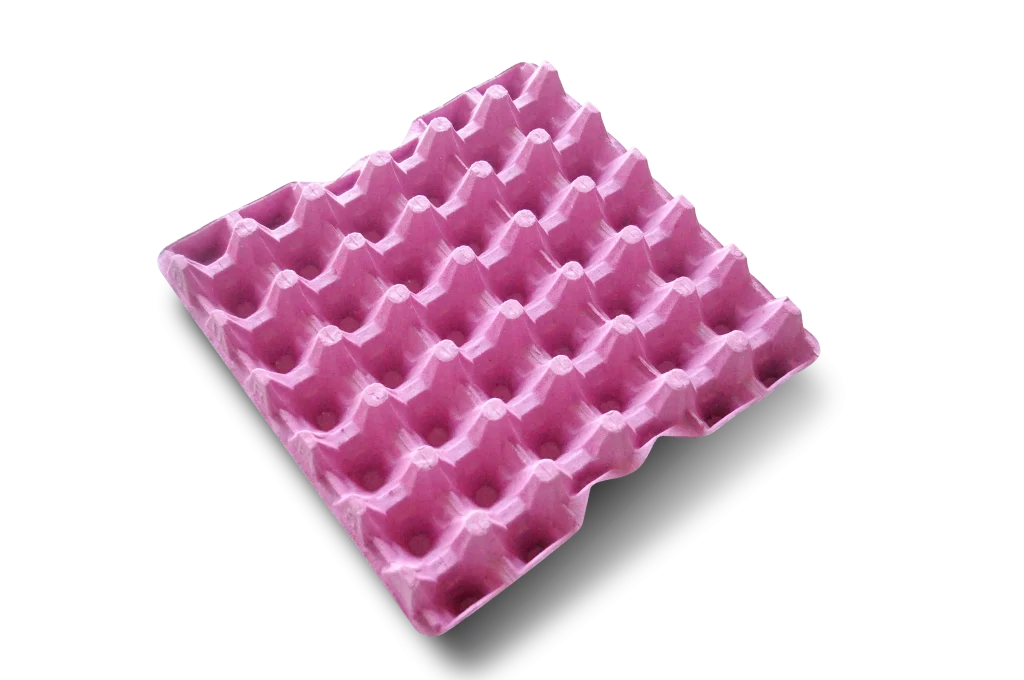

The egg tray manufacturing process is a systematic procedure that begins with the gathering of essential materials, primarily recycled paper pulp. This eco-friendly raw material is not only abundant but also plays a crucial role in promoting sustainable practices within the packaging industry. The use of recycled paper ensures that the production of egg trays minimizes waste and reduces the environmental footprint associated with traditional materials.

The initial stage of the process involves preparing the paper pulp, which requires shredding, soaking, and blending the recycled paper with water to create a slurry. Once the pulp is prepared, it is transferred to a molding machine, where various methods can be employed for shaping. The most commonly used technique is known as the pulp molding process, which allows for efficient production of egg trays in various sizes and configurations. Other techniques, including vacuum forming or pressure forming, may also be applied depending on specific requirements and production capacities.

After the molding process, the formed trays undergo a drying phase, which is critical in ensuring durability and strength. This step can be achieved through natural sunlight or through controlled drying methods such as heat exchangers or convection ovens. Once adequately dried, egg trays are thoroughly inspected for quality assurance before proceeding to the packaging phase. The trays are then stacked, bundled, and prepared for distribution to clients, ensuring that they meet industry standards for safety and performance.

In conclusion, the egg tray manufacturing process involves several critical steps from material preparation to final packaging. Utilizing recycled paper pulp not only promotes environmental sustainability but also enhances the overall quality of the egg trays produced. Understanding the nuances of this process is essential for anyone considering an investment in this growing industry.

Key Equipment for Egg Tray Production

Starting an egg tray making business requires the right machinery to ensure efficiency and quality in production. The egg crate making machine is the centerpiece of this operation. There are various types of machines available, ranging from manual to fully automated systems, each designed to cater to different production scales and budgets. The choice of machinery can significantly affect the operational workflow and overall product quality.

Manual egg tray making machines are ideal for small-scale operations. These machines generally require manual labor for production but are cost-effective and suitable for entrepreneurs just starting. They are easy to operate and do not involve significant initial investments. However, their production capacity is limited when compared to larger automated systems.

On the other hand, semi-automatic and fully automatic egg tray making machines are designed for larger businesses aiming for high production volumes. The fully automatic models come equipped with advanced features including automatic feeding, molding, drying, and stacking systems. The use of these machines can drastically reduce labor costs and accelerate the production process. When investing in automatic machinery, it’s essential to consider the maintenance requirements and the availability of after-sales support to avoid unforeseen production interruptions.

Another important consideration is the choice of pulp material, as it impacts the quality of the egg trays. Quality machines provide consistent shaping and drying, ensuring that the final product meets required standards. Additionally, businesses should evaluate energy consumption as part of their cost analysis, since operating expenses can rise substantially with inefficient machines.

When selecting the right equipment for an egg tray making business, it is crucial to assess production needs, business scale, and budget. Investing in the appropriate machinery can lead to enhanced productivity and product quality, setting the foundation for a successful venture.

Market Potential and Profitability of Egg Tray Business

The egg tray manufacturing business presents significant market potential, particularly in a world increasingly focused on sustainable practices. As consumers and businesses strive to find eco-friendly packaging solutions, the demand for biodegradable and recyclable egg trays has surged. This increasing significance of sustainable packaging in the egg industry cannot be overstated, as it not only fulfills environmental responsibilities but also aligns with consumer expectations for responsible product sourcing.

Potential customers within this market include a variety of stakeholders such as poultry farmers, egg producers, and distribution companies. These entities require reliable packaging solutions to ensure the safe transportation and storage of eggs. By offering high-quality, durable egg trays, manufacturers can establish long-term partnerships with these customers, generating a steady revenue stream. The shift towards automation in poultry farming has further heightened the need for effective packing materials, thus presenting an untapped opportunity for egg tray producers.

To maximize profit margins, egg tray manufacturers should adopt competitive pricing strategies, factoring in production costs, materials, and market rates. A clear understanding of the target market and pricing trends will aid in establishing prices that reflect both value and affordability. Moreover, positioning the product as a sustainable alternative can justify premium pricing, appealing to environmentally-conscious buyers.

Examining case studies of successful enterprises within the egg tray manufacturing sector reveals a trend of profitability linked to innovative production methods and efficient supply chain management. Businesses that focus on quality control and sustainability not only enhance their brand reputation but also improve their profit margins. Overall, the egg tray manufacturing business emerges as a lucrative opportunity, with substantial growth in demand expected in the foreseeable future, particularly in light of global sustainability initiatives.

Starting and Managing Your Egg Tray Business

Embarking on the journey of starting an egg tray making business requires comprehensive planning and execution. The first step is to develop a robust business plan that outlines your vision, objectives, target market, and financial projections. This plan will act as a roadmap, guiding you through the complexities of entrepreneurship.

Once your business plan is in place, the next critical aspect is sourcing raw materials. Typically, egg trays are made from recycled paper waste, which can be procured from local suppliers or recycling facilities. Establishing reliable relationships with these suppliers is essential for ensuring a consistent and sustainable supply of materials. Consider conducting market research to identify the best sources of quality paper pulp at competitive prices.

Setting up production facilities is another crucial stage in launching your egg tray making business. This involves selecting an appropriate location that adheres to local zoning regulations and has ample space for machinery, storage, and product distribution. You will need to invest in specialized machinery that can handle the pulping process, molding, and drying of the trays efficiently. Often, it is beneficial to acquire machinery that minimizes waste and maximizes energy efficiency, aligning with best practices for sustainability.

Marketing your egg trays effectively is essential to attract clients and increase sales. Identify your target market—ranging from local farms to retail businesses—and develop a marketing strategy that addresses their needs and preferences. Utilizing digital marketing channels such as social media, e-commerce platforms, and a dedicated website can significantly enhance your reach and visibility.

Lastly, ensure compliance with relevant regulatory requirements. This often includes obtaining necessary permits and certifications to operate within legal frameworks. Being aware of industry standards not only legitimizes your business but also fosters customer trust. By combining these elements—strategic planning, efficient operations, and compliance—you can establish a successful egg tray production business, primed for growth and sustainability.