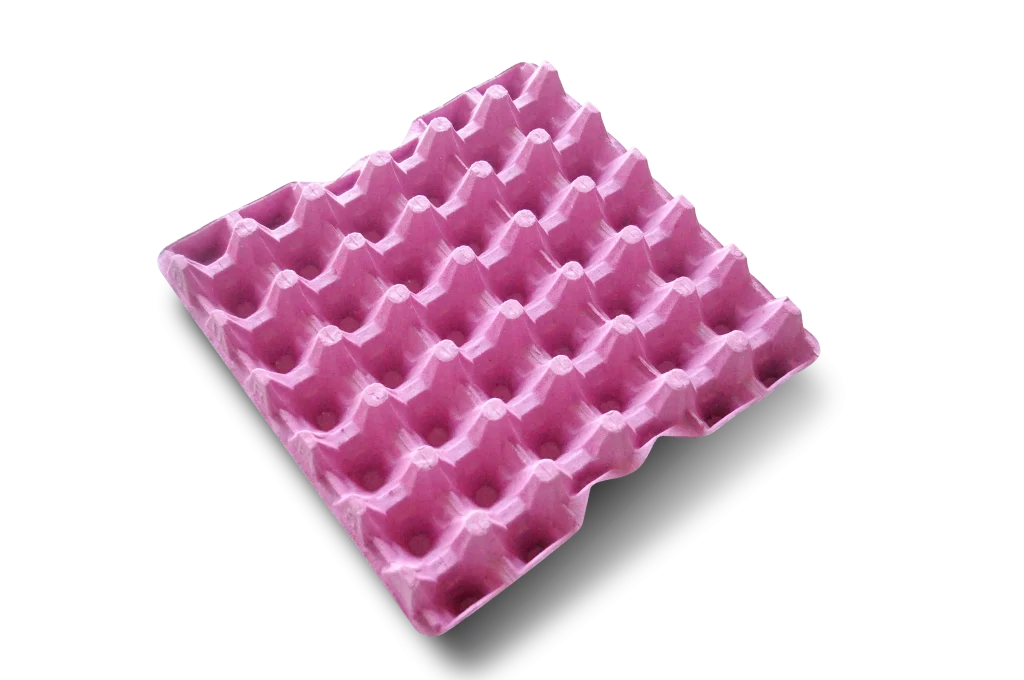

In the poultry industry, effective egg packaging solutions are essential for ensuring the safe transport and storage of eggs. The primary function of egg packaging is to protect eggs from damage during handling and transit, while also preserving their quality. The various egg packaging types—namely egg crates, cartons, and boxes—serve distinct purposes in this regard, each designed to meet specific requirements based on the quantity and destination of the eggs.

Egg crates, typically made from molded pulp, are often used in the initial collection and transportation of eggs from farms to processing facilities. They allow for ventilation, minimizing the risk of condensation and microbial growth. On the other hand, egg cartons, available in various materials including plastic and cardboard, provide a more retail-friendly packaging solution. They not only offer protection but also enhance the presentation of the eggs to consumers. For large-scale shipments, egg boxes serve as a practical option, enabling bulk transportation and storage while maintaining the integrity of the eggs.

The demand for sustainable packaging solutions has been steadily rising, driven by environmental concerns and consumer preferences. Manufacturers are increasingly turning to eco-friendly materials and processes, minimizing waste and promoting recyclability. Innovations in machinery have played a significant role in this shift. Advanced egg crate, carton, and box making machines are now capable of producing packaging that is both efficient and environmentally conscious. These machines often incorporate automated systems that enhance production speed and reduce material usage, meeting the dual goals of cost-effectiveness and sustainability.

As the poultry industry continues to evolve, understanding the various egg packaging solutions and the machinery used in their production remains vital for producers and retailers alike. This comprehensive guide aims to delve deeper into the specifics of egg crate, carton, and box making machines, thereby providing valuable insights into their impact on the poultry supply chain.

Egg Crate Making Machines: Features and Benefits

Egg crate making machines are specialized equipment designed to manufacture protective egg packaging products. These machines operate through a systematic process that begins with pulp preparation, where raw materials like recycled paper and cardboard are converted into pulp. This pulp is then fed into a molding section, forming the characteristic shapes of egg crates. The details of the machine’s operation can vary, but efficiency and quality control are paramount in modern designs.

One major feature of egg crate making machines is their ability to handle various materials. While the most common input is recycled paper, some advanced machines can also utilize agricultural waste or wood pulp, thus promoting sustainability within the production process. The choice of material can affect not only the final product’s quality but also production costs and environmental impact.

Capacity is another significant aspect of these machines. They are available in various configurations to cater to different production scales—ranging from small-scale, manually operated units to large, fully automated systems capable of producing thousands of units per hour. This flexibility allows businesses to choose machines that best suit their operational scale and market demands.

Customization options are increasingly prevalent, with manufacturers offering bespoke solutions tailored to specific needs, including varying crate sizes and shapes. This adaptability ensures that businesses can meet the requirements of diverse clients while providing the opportunity to expand product lines in the future.

Furthermore, automation has transformed the egg crate manufacturing industry. Automated egg crate making machines minimize labor costs by reducing the need for manual intervention, which concurrently enhances production speed and ensures consistent quality. The integration of advanced technology, such as real-time monitoring systems, allows for immediate adjustments, improving the overall reliability of the production process.

HGHY EGG TRAY MACHINE

The egg tray machine is the most important equipment in the egg tray production line. If you are struggling with how to deal with a large number of discarded cartons, magazines, papers, and old books, and wondering how to turn waste into treasure, the pulp egg tray production line is a great solution for you.

Egg Carton Making Machines: Overview and Functionality

Egg carton making machines serve a crucial role in the packaging industry, specifically in the production of containers designed to protect eggs during transport and storage. Unlike crate making machines which cater to larger agricultural products, egg carton machines are specialized in producing molded pulp containers tailored for eggs. These machines operate by converting raw materials, primarily recycled paper and cardboard, into durable egg cartons, ensuring the eggs remain safe from damage.

The designs of egg cartons can vary significantly, ranging from traditional paper-based options to modern plastic alternatives. Paper-based egg cartons are typically made from recycled materials, aligning with sustainability efforts within the packaging industry. On the other hand, plastic egg cartons may offer enhanced durability and moisture resistance, catering to different market needs. Egg carton making machines are engineered to produce various styles and sizes, accommodating standard egg sizes as well as specialty types, such as quail or organic eggs, ensuring flexibility for manufacturers.

Innovation in the design of egg carton making machines has led to enhanced efficiency and reduced environmental impact. Contemporary machines employ advanced technologies, allowing for greater precision in production while minimizing waste. Many manufacturers are now integrating energy-efficient processes that not only lower production costs but also support eco-friendly initiatives. Additionally, with growing consumer awareness regarding sustainability, the demand for recyclable and biodegradable egg cartons continues to rise.

In conclusion, egg carton making machines represent a vital component of efficient egg packaging, balancing functionality with environmental considerations. Their adaptability in design and production capacity makes them an essential investment for businesses in the agricultural sector.

Choosing the Right Egg Box Making Machine: Key Considerations

When selecting an egg box making machine, it is essential to evaluate several pivotal factors that can significantly influence the efficiency and effectiveness of operations. First and foremost, production volume is a critical determinant. Businesses must gauge their production requirements, as varying machines offer different capacities. A facility that requires a high throughput may need a more advanced model, while a small operation might manage with a more compact machine. Understanding production demands helps in selecting a machine that aligns with business objectives.

Another crucial aspect to consider is the type of packaging required. Different businesses may have unique preferences for the shape, size, and design of egg cartons. Therefore, it is prudent to select a machine that can accommodate various packaging specifications. This adaptability not only enhances the product appeal but also caters to specific customer demands, providing a competitive edge in the market.

Budget constraints often dictate the purchase of machinery, making it essential for businesses to establish a clear financial plan before proceeding. The initial cost of the egg box making machine should be weighed against long-term operational costs, including maintenance and energy consumption. While it may be tempting to opt for the lowest price, investing in a high-quality machine that offers durability and efficiency can lead to considerable savings over time.

Additionally, assessing the available space for the machine is vital. Ensuring that there is sufficient room for the machine, as well as for the necessary workflow, storage for raw materials, and finished products, will facilitate smooth operation. Furthermore, operators should consider the reliability of potential suppliers and the level of after-sales support they offer, which can be invaluable for ongoing maintenance and troubleshooting. The combination of these factors will guide businesses in making an informed decision regarding their investment in egg box making technology.